Main structure introduction and function of textile screen printing machine

With the development of the printing industry, more and more screen printing machines are used, and the industry span is also very large, ranging from advertising materials to urban construction, etc., which seem to be inseparable from the use of screen printing machines. Textile screen printing machines also play an important role in the packaging and printing industry.

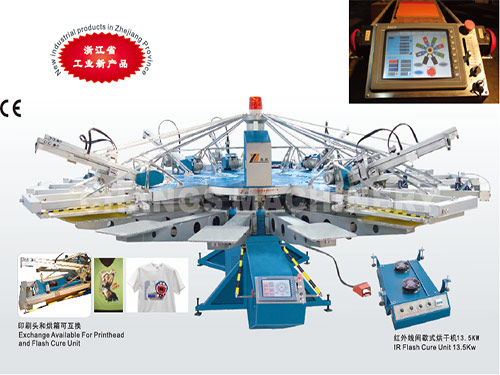

The main structure of the textile screen printing machine:

(1) Color touchscreen operation interface

(2) The servo drive system can provide high-speed running speed while ensuring stable printing, durability, and long life

(3) The net distance of each station (the distance between the screen and the surface of the substrate) can be adjusted precisely at the same time

(4) Double shift function improves the printing quality

(5) Fast pneumatic platform has a replacement function

(6) The turntable can rotate clockwise or counterclockwise

(7) The frame can be assembled with an oven, printing head, and flocking printing head according to the needs

(8) Manual tap jumper switch can avoid empty table printing

(9) Thick plate printing and automatic plate change function are optional

The main structure of the screen printing machine:

(1) Transmission system device: electric motor, electromagnetic brake, reducer, speed change mechanism.

(2) Printing plate device: The metal screen printing plate must be fixed on the printing plate device in the screen printing machine. During the printing process, they must take off the book or lift it horizontally. The key points are the printing plate lathe fixture, printing plate lift-off, and landing mechanism, plate alignment adjustment mechanism, and net lifting compensation mechanism.

(3) Packaging and printing device: ink scraping and ink return are the key actions to maintain screen printing ink. The ink scraping system and ink return system are generally installed on the scraper sliding wall. During repeated movements, the ink scraper and ink return The boards take off and land alternately, and each maintains the ink scraping and ink return postures.

① To maintain the reciprocating schedule of packaging and printing, the following mechanisms are generally used: guide rod crankshaft mechanism, guide rod guide rail slider mechanism, chain sprocket mechanism, and cylinder plug magnetic field cylinder.

② The guiding mechanism generally adopts the following methods: roller groove rail, double guiding shaft, guiding shaft plus guide rail slider.

③The interchange mechanism of scraping and ink return boards often adopts the following methods:

Stairway elevator impact block plus lever interchange mechanism, camshaft lift mechanism plus lever interchange mechanism, two cylinders in the opposite direction or single cylinder plus lever mechanism, camshaft-swing rod mechanism drives stainless steel wire plus lever mechanism, transmission chain hanging point The change makes the two plates swing at an angle. When replacing two scrapers with one scraper, an ink jumping action is required, and the ink jumping action is carried out by a special mechanism.

The support plate device is the printing process service platform: it is used to fix the printing process.

① There should be a precise positioning device for printed parts.

②The height and level adjustment device of the platform.

(4) Alignment mechanism: The position of the platform moves during alignment, which is generally maintained by mechanical thread rotation, and requires a reliable clamping device and movement guidance (dovetail groove or guide key, etc.).

(5) Drying device: Infrared heating tube warm air drying or UV curing air drying device.

(6) Electrical control device: working cycle control, scraper position control, air pressure control.

The role of textile screen printing machine

Textile screen printing machine puts the ink on the screen plate and moves the accumulated ink and the screen plate back and forth on the screen plate through the scraper so that the screen plate and the product to be printed are on the same pressure line, and the ink is on the screen of the screen plate. The holes penetrate the product to be printed, and the patterns, characters, patterns, etc. on the screen can be displayed on the product to be printed. All models can be printed on T-shirts, sleeves, bed sheets, and textile bags.

If you want to know more about the textile screen printing machine, please pay attention to the website

English

English 中文

中文