Technical advantages of screen printers, purchasing skills, factors affecting the price of screen printing machines

What are the technical advantages of screen printing for Screen Printers?

The screen printing of the Screen Printer is stretching the silk fabric, synthetic fiber fabric, or metal screen on the screen frame, and using the method of manual engraving paint film or photochemical plate making to make the screen printing plate, and then the printing plate (paper film plate or another plate) When printing, the ink is transferred to the substrate (paper, ceramics, etc.) through the holes of the stencil through a certain pressure to form images or characters. Modern screen printing technology is to use photosensitive materials to make screen printing plates through photo-plate making (making the screen holes of the graphic part on the screen printing plate be through holes, and the screen holes of the non-graphic part are blocked). During printing, through the extrusion of the scraper, the ink is transferred to the substrate through the mesh of the graphic part, forming the same graphic as the original. The Screen Printer used in screen printing technology is simple, easy to operate, easy to print and plate-making, low in cost, and strong in adaptability. Screen printing has a wide range of applications, and commonly printed materials include color oil paintings, posters, business cards, bound covers, commodity signs, and printed and dyed textiles.

What are the tips for choosing a Screen Printer?

Choosing a Screen Printer also has different selection skills according to the specific industry, but in general, how to choose a Screen Printer is very particular. Each Screen Printer device has its specific scope of application, and several drying devices can meet the basic requirements for each material, but only one is the most suitable.

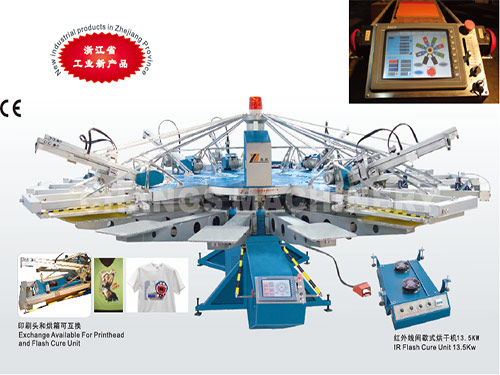

There are many types of Screen printers according to the printed products. Below, Changs Machinery will share with you some tips for purchasing Screen Printer:

1. Cylinder screen printing: Cylinder screen printing is a printing method in which a cylinder screen plate is equipped with a fixed squeegee, and the cylinder plate and the substrate are moved at equal linear speeds synchronously.

2. Indirect screen printing: In the first three methods, the printing plate directly prints the substrate, but only some regular geometric shapes, such as plane, cylindrical surface, conical surface, etc., are used for complex shapes, corners, and depressions. Surfaces and other special-shaped objects must be printed by indirect screen printing. The process usually consists of two parts: flat screen printing and transfer printing, that is, the screen printing image is not directly printed on the substrate, but printed first. On the flat material, it is transferred to the substrate by a certain method. One of the methods of indirect printing is to first print the image on the flat glass by flat screen printing, and then use a flexible silicone head to absorb the ink image from the glass plate like a stamp, and then transfer it to the special-shaped surface. Surface: Another method of indirect screen printing is decal transfer printing, such as screen printing decal + thermal transfer, screen printing decal + pressure-sensitive transfer, and screen printing decal + solvent activation print. Indirect screen printing has become a major field in the printing industry.

3. Flat screen printing: flat screen Printer is a method of printing on a flat substrate with a flat-screen plate. When printing, the printing plate is fixed and the scraping plate moves.

4. Flat screen curved surface screen printing: Flat screen curved surface screen printing is a method of printing a flat screen printing plate on a curved surface substrate (such as a ball, cylinder, cylinder, etc.). During printing, the squeegee is fixed, the printing plate moves horizontally, and the substrate rotates with the printing plate.

5. Screen Printer usually manufactured by domestic Screen Printerry manufacturers are generally divided into two categories: oblique arm (hinge) type Screen Printer and vertical horizontal scraping type Screen Printer. There are also pneumatic and electric types for subdivision.

6. Features of the oblique arm type Screen Printer: it drives the hinge-like lifting of the body through the rotation of the crankshaft, and the stress point of its frame is inconsistent (like a scale beam). This is also a defect of this kind of Screen Printer (this is a structural defect, which has nothing to do with the manufacturing accuracy of the manufacturer). You must know that the force points of the screen pattern must be evenly pressed to print high-quality screen printing products. The oblique arm Screen Printer is prone to inconsistencies in front and rear pressure.

7. The vertical horizontal scraping Screen Printer makes up for this shortcoming. It adopts the linear guide rail horizontal scraping movement, and the pressure of each point is consistent when printing the pattern. For screen printing, the ink layer requires uniform electronic product silk screen printing and multi-color overprinting. The best choice, it is also characterized by intuitive and clear operation, simple and fast assembly and disassembly of the screen plate, convenient and stable pressure adjustment, and easy training for new workers.

What are the major factors that affect the price of Screen Printers?

Here, Changs Machinery would like to remind friends who need to know the price of the Screen Printer. The main printing factors that affect the price of Screen Printers are as follows: 1. Materials; 2. Accessories; 3. Assembly capacity; 4. Packaging and transportation methods ;

1. The choice of material is one of the main factors affecting the price of the Screen Printer; in fact, the reason is very simple, the thickness of the steel that looks the same in appearance cannot be seen; this is a big difference, the thickness is large The price of thinner steel is not as simple as one or two times lower than the price of thinner steel. To save materials, inferior raw materials are used for thinner steel, which is light and easy to bend and rust; the Screen Printer produced by Chang's Machinery are all made of national standard steel. , Never use non-standard and inferior materials. The advantage of this is that the Screen Printer produced has a stable structure, high durability, and reliable printing quality;

2. The difference in accessories is one of the main factors affecting the price of Screen Printers; everyone knows that the price of counterfeit products is very cheap, and the same is true for the selection of Screen Printer accessories. Accessories of the same specification, from Taiwan The price of buying or buying from abroad is much more expensive than buying in Shenzhen in Zhejiang, then the problem comes, the same solenoid valve, there are more than a dozen models, there are more than one hundred, the price difference is ten times, laymen can't see it. There is no difference if there is no difference; the Screen Printer accessories used by Chang's Machinery are all original big-name accessories so that the Screen Printer is reliable and safe;

3. Assembly capacity is also one of the main factors affecting the price of Screen Printers; Screen printers installed by different masters are different, the equipment assembled by experienced masters is smooth, the various coordination is better, and the equipment is easy to use. It is relatively simple; the equipment assembled by poor masters has poor stability and may take longer to run in; at the same time, the wages of experienced masters are several times higher than that of ordinary masters. We all hire experienced workers with high salaries. Professional masters ensure the reliability of equipment assembly and deliver perfect equipment to your hands;

4. Packaging and transportation capacity is also one of the main factors affecting the price of Screen Printer; stable packaging, and timely and efficient transportation is our criterion; Changs Machinery especially employs professional wooden box packaging masters, and the packaging is stable and reliable, and there is almost no time during transportation. There have been accidents; at the same time, Changs Machinery cooperates with big-brand transportation companies to ensure timely, efficient, and reliable transportation;

Therefore, everyone should not say that the price is expensive. We must clearly understand what kind of structure, what kind of accessories, and what kind of workmanship the equipment adopts so that we can choose the right equipment.

English

English 中文

中文