The prospect of automatic screen printing machine and T-shirt customization with screen printing or heat transfer printing?

Can screen printing be automated? Screen Printing Prospects

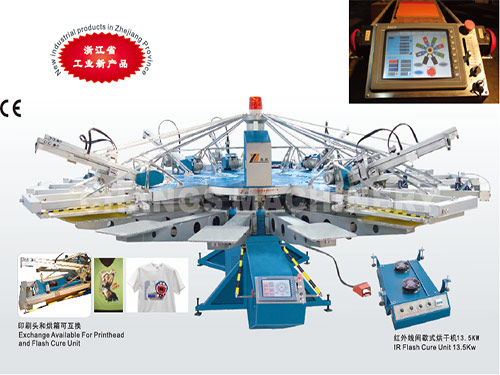

After thousands of years of development and the continuous development of printing technology, there are many types of screen printing machines, and now the emergence of fully automatic screen printing machines has made the printing industry more intelligent. When the trend of industrial automation spreads to all walks of life, the screen printing industry also perceives the opportunities brought by the trend of the times. The process of screen printing automation seems to be relatively smooth in other fields.

Which is better, screen printing or heat transfer printing

(1) The ink layer of silk screen printing is relatively thick, and the ink layer of heat transfer printing is relatively thin, which can be judged from the simple feel.

(2) Silk screen printing is simple, with large dots and low image resolution. The effect of thermal transfer graphics is good, the color is bright, and the graphics are exquisite;

(3) The initial investment cost of silk screen printing is low, and the initial investment cost of heat transfer printing is relatively high.

(4) Heat transfer printing uses a heat transfer machine to print pictures, and screen printing uses screen printing to print pictures.

(5) The automatic screen printing machine manufacturer tells you that silk screen printing is to use a screen plate to squeeze the printed content to adhere the ink to the product. Thermal transfer printing is a process that uses a special film to adhere the content of the film to the product after heat treatment.

Is it better to use silk screen printing or heat transfer printing for customized T-shirts?

Screen printing is the most common printing process. 90% of the T-shirts sold in the market now use this printing method. The process of screen printing is relatively complicated, usually including design, printing, printing, printing, and drying. Do several steps. Screen printing, simply speaking, is that if the pattern of a T-shirt has three colors of red, yellow, and blue, then three plates need to be printed, one for each color, but it is a bit different from the CMYK printed. Similarly, most domestic printing is spot color printing, and the superimposition of CMYK dots is difficult to control in T-shirt printing.

Overly complex images cannot be completely printed by screen printing. At this time, a new printing technology is produced, that is, thermal transfer printing. Thermal transfer printing can be said to be a supplement to screen printing. Simply put, transfer printing is pressing special paper with pictures on it to the clothes through a heat transfer machine. Its advantage is that the printing pattern is vivid in color, and more importantly, it is fast and convenient. The disadvantage is that some light-colored patterns are not clear enough, and the places where the pictures are printed are not breathable. T-shirts made by heat transfer printing are generally suitable for making a large number of disposable cultural shirts for group activities.

Four main uses of automatic screen printing machine

(1) Packaging and printing

Packaging printing is now the most common screen printing product. For example, the pattern text on the packaging gift box is processed by a screen printing machine.

(2) Handicraft printing

When it comes to handicraft printing, it is inevitable to think of ceramic products, such as tiles. The patterns and patterns on the tiles are lifelike. With the development of the tile production line, the use of screen printing has become a common trend.

(3) Advertising printing

I believe there is no need to explain too much about this. Walking on the street, the posters on the bus stop, the electrical advertisements outside the building walls, and the commercial advertisements at the elevator entrance, etc. are all advertisements printed by silk screen printing machines.

(4) Circuit board printing

Circuit board printing is an industry that has emerged in recent years. With the development of electronic products, the market prospect of circuit board printing is promising. In the field of the electronics industry, the use of screen printing reaches 80%.

How to run the automatic screen printing machine?

(1) Before work, the power switch must be turned from green 0 to white 1, and make sure that the main power supply has turned on all the ventilation equipment and keep it running normally;

(2) Wait for the computer to start automatically. After starting, the printing control program will be automatically loaded. The operator must wear protective masks and rubber gloves correctly before operating;

(3) Take out the screen plate of the corresponding model, fix it on the screen plate fixing frame, install it on the machine, and press the F4 key to lock the screen plate. At the same time, you can hear the sound of "pop", and you can feel that the screen plate will not be able to be pulled out with your hands. Install the scraper and ink return knife, and transfer the corresponding process file.

(4) Ink, acetone, and other chemical raw materials or auxiliary materials can only be collected for on-duty use, and stored in a dedicated storage cabinet, kept sealed, and must not be placed on the ground or the workbench;

(5) All kinds of cleaning cloths, papers, environmental protection bowls, disposable plastic cups, stirring rods, and other chemical wastes that are stuck with chemicals should be put into special trash cans, and the lids should be covered to keep them sealed. Littering is prohibited;

(6) When repairing, cleaning, and maintaining the equipment, replacing and adjusting parts and accessories, the power supply and air source must be turned off before leaving get off work, and the site must be cleaned before leaving get off work.

How does the automatic screen printing machine work?

The text and images to be printed are first made into a printing plate and installed on the printing machine, and then the ink is applied manually or by the printing machine to the place where the text and images are on the printing plate, and then directly or indirectly transferred to paper or other printing materials On objects (such as textiles, metal plates, plastics, leather, wood, glass, and ceramics) to reproduce the same print as the printing plate.

Screen printing process

(1) Screen selection

① Nylon screen: Nylon screen has high strength, high wear resistance, high alkali resistance, slightly poor acid resistance, good ink permeability, small wire diameter, good elasticity, and clear imprint;

②Polyester screen: The polyester screen has good stability, high strength, corrosion resistance, better performance than nylon screen, high stretching tension, suitable for high-precision printing;

③ Stainless steel wire mesh: stainless steel wire mesh has high strength, good stability, small wire diameter, high mesh, good resistance, long life, poor elasticity, easy to break under the impact, suitable for precision printing, not suitable for curved surface printing;

④ Nickel-plated polyester wire mesh: Nickel-plated polyester wire mesh combines the advantages of polyester mesh and stainless steel mesh, with wide applicability, moderate price, and poor corrosion resistance.

(2) Stretching net

There are wooden frames, metal frames, plastic frames, combination frames, etc. for the screen version. When stretching the net, the net frame should be cleaned first, and the net can be stretched manually, mechanically, or pneumatically, and then glued and trimmed after stretching. Stretching requires that the tension of the wire mesh is appropriate, uniform, and stable, that the wire direction is consistent to avoid oblique pulling, and the warp and weft wires are parallel to each other.

(3) plate making

① Direct method: screen cleaning → photosensitive glue coating → printing → development → revision. This method is time-consuming for gluing, the film thickness can be adjusted, the combination is firm, it is resistant to printing, and the graphics and text are easy to jag.

②Indirect method: photosensitive film→printing→developing→sticking film→removing film base→repairing. This method is complicated to operate, the lines are smooth, the film is not firm, the printing resistance is low, and the thickness of the film remains unchanged.

③Mixed method: screen cleaning→film patch→printing→developing→retouching. This method is easy to operate, the thickness is fixed, and the lines are smoother and firmer.

(4) Screen direct plate making

①Laser ablation direct plate making: first coat the screen photosensitive adhesive on the metal screen, and burn through the photosensitive layer with laser, the mesh part of the graphic and text is transparent, and the computer of the prepress system controls the ablation place. This method can only be used for metal nets.

②Laser exposure direct plate making: First, apply photosensitive glue on the screen, and the prepress system computer controls the laser to image on the screen to make a screen plate. This plate-making method uses a special photosensitive glue, the ultraviolet light wave range is narrow, and the price of the laser exposure system is high.

③Inkjet imaging system: First, apply photosensitive glue on the screen, and the prepress system computer controls the inkjet system to spray light-blocking ink onto the photosensitive layer of the graphic part, and then fully expose it to ultraviolet rays. The graphic part is not photosensitive, and the photosensitive glue is washed away; the blank part is photosensitive and hardened. This method can use ordinary photosensitive glue without losing the details of the image.

What is screen printing?

Screen printing is to stretch silk fabrics, synthetic fabrics, or wire mesh on the screen frame, and adopts the method of manual engraving paint film or photochemical plate-making to make screen printing forme.

The application range of screen printing machines: liquid crystal glass, lens glass, packaging box, light-emitting film, sheet glass, mobile phone lens, display screen, panel, nameplate and acrylic film, touch screen, light guide plate, TV, circuit industry, plastic bag, photoelectric Industrial, single, double-sided, multi-layer circuit boards, PCB boards, liquid green oil, a flash film, flexible circuit boards, flexible circuits, membrane switches, IMD, IML, self-adhesive, heat transfer film, trademarks, labels, nameplates, Non-woven bags, etc.

No matter what type of screen printing machine is, it has different characteristics, and different screen printing machines have different prices. No matter what kind of screen printing machine, there is an adaptation process at the first contact. In this regard, we should conduct a detailed analysis of our own needs before purchasing, and at the same time have a detailed understanding of what suits us. Only in this way can we buy a screen printing machine that suits us.

English

English 中文

中文